Optical R&D

Hornix has professional optical and mechanical design capabilities, we can provide the corresponding optical simulation according to the customer’s demand for laser light type, , then use the super finishing equipment to make the mold. Using the high stability injection machine to make plastic injection molding and module assembly, provide customers a complete total solution service.

Early Development

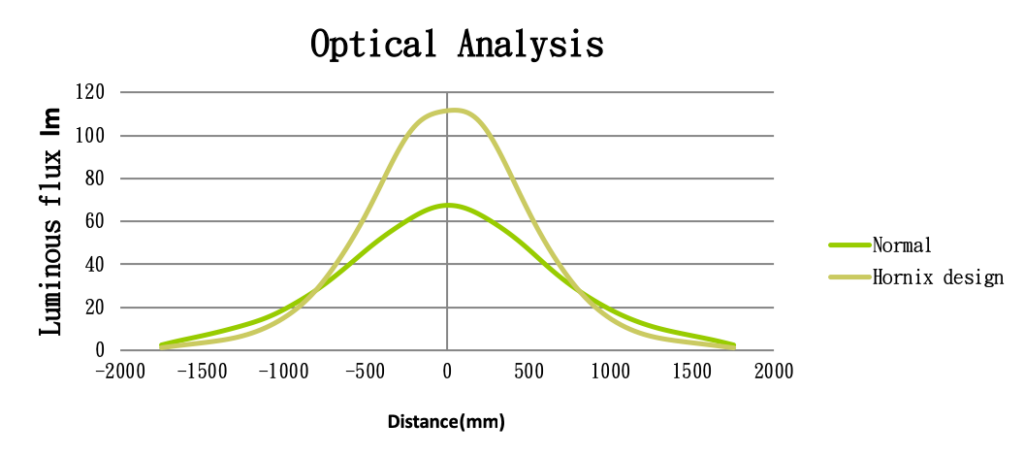

Optical Analysis

Develop the design with customers in the early stage, reducing the product failure rate and improving mass production.

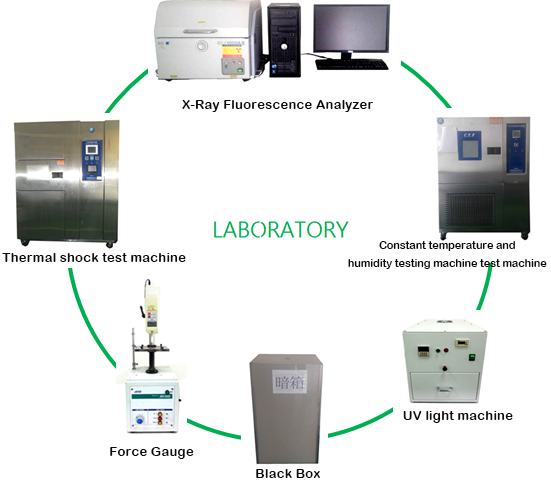

Laboratory Equipment

Technical Ability Introduction

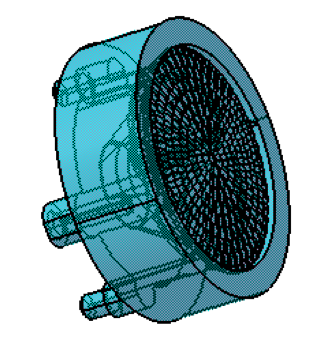

- Precision plastic mold

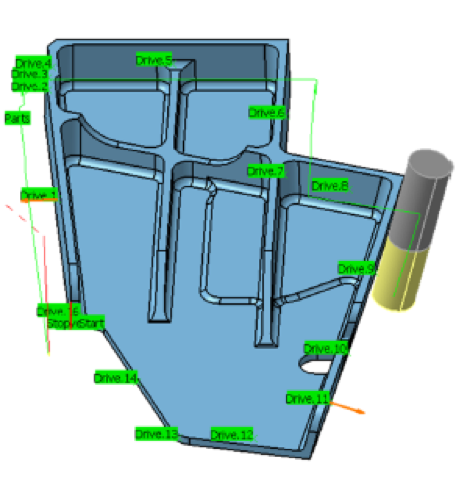

Mold structure and mold flow analysis

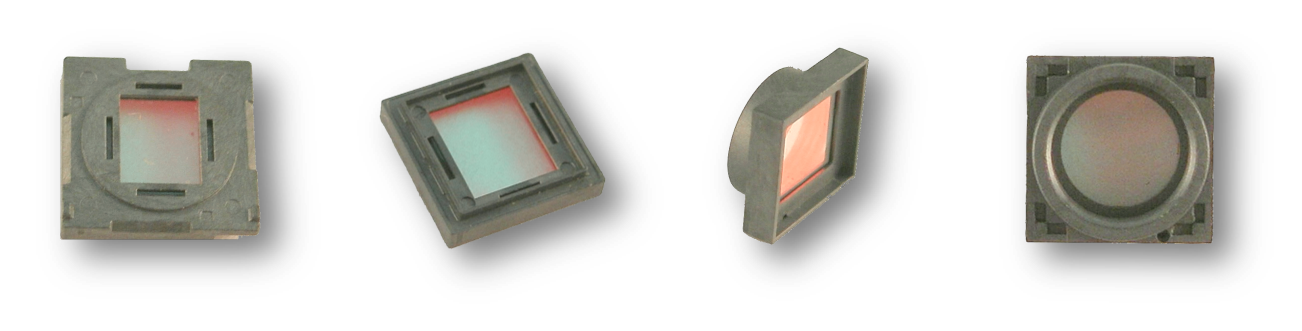

- LC Liquid Crystal Glass Film Insert Injection Technology

- Optical level Simulation Analysis

Professional services, precision optical grade mold opening and design, optical analysis, etc.

- Nonlinear Ultra-precision Processing & Mold

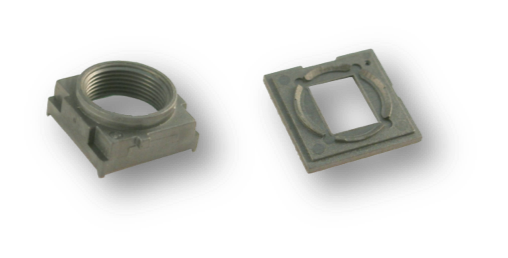

Precision Plastic Mold

- Own extensive experience in mold making and design capabilities.

- Confirms mold structure design by Mold flow analysis

- Mold opening technology improves stability.

- The soft tooling mold can be maked in a two-week schedule, provide customers with a quick sample service.

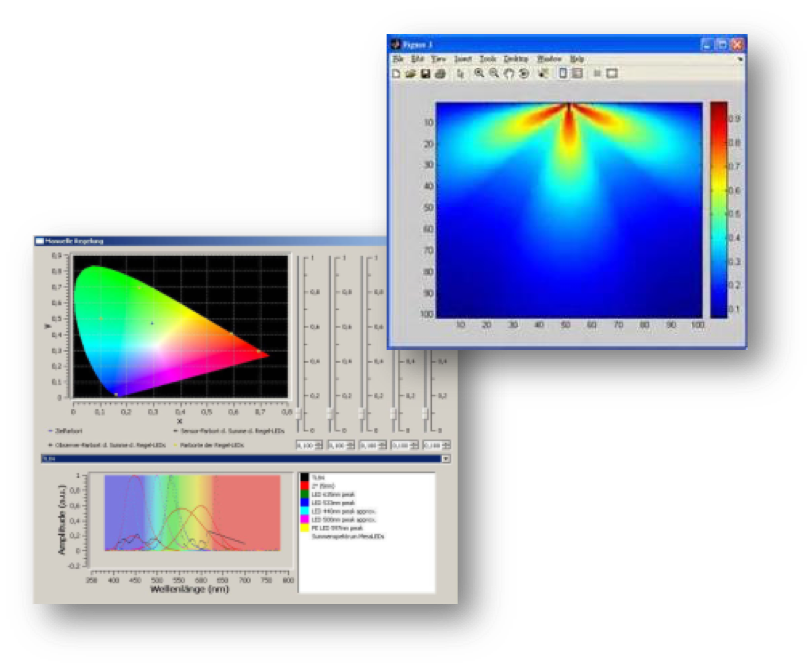

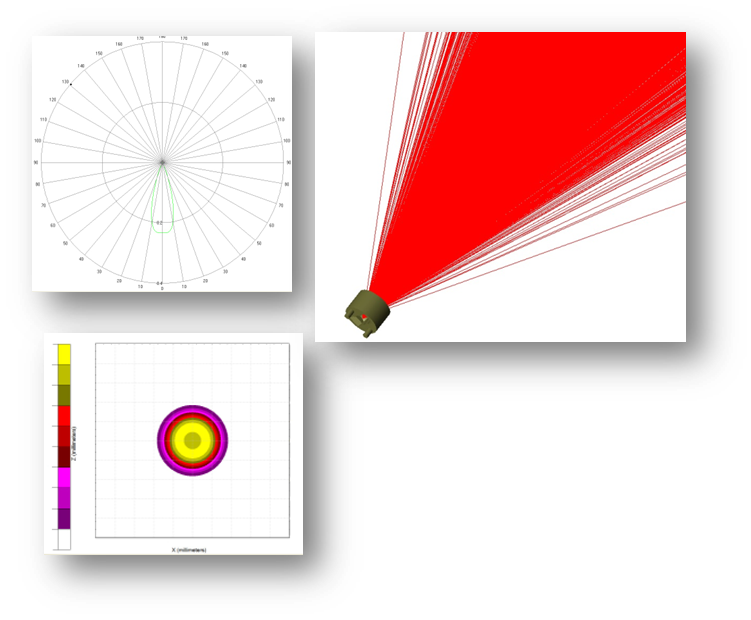

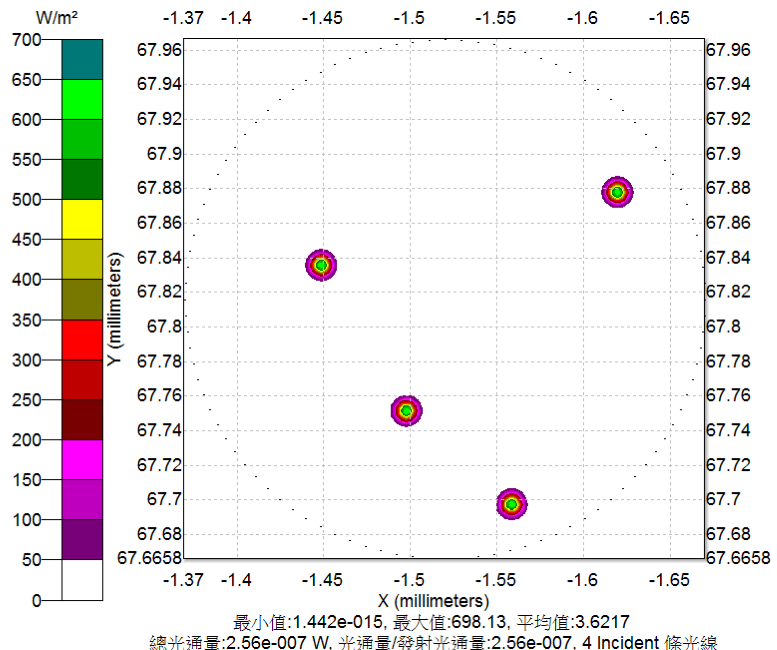

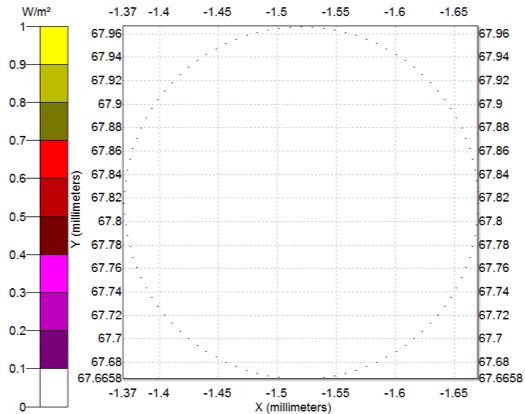

Professional Optical Simulation Analysis

Optical grade LENS requirements, providing professional optical simulation analysis and cross-checking with practice to verify product functionality. Darkroom Laboratory Verification Product Light Type.

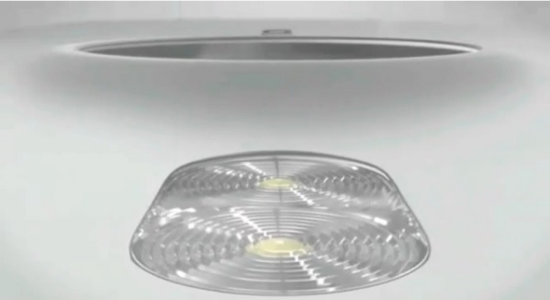

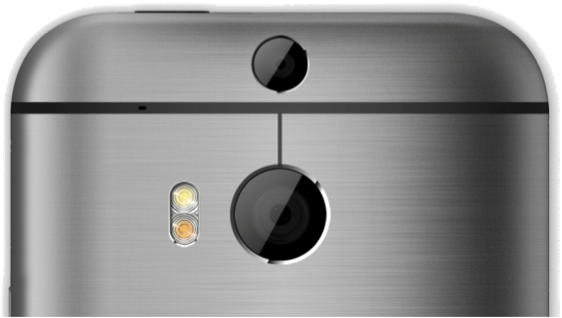

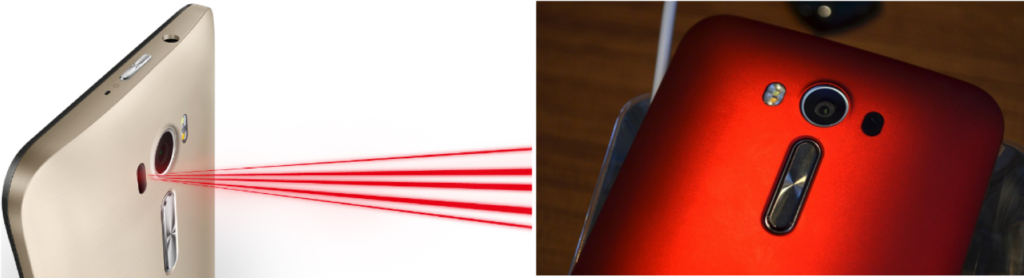

Flash Application Smartphone & Tablet

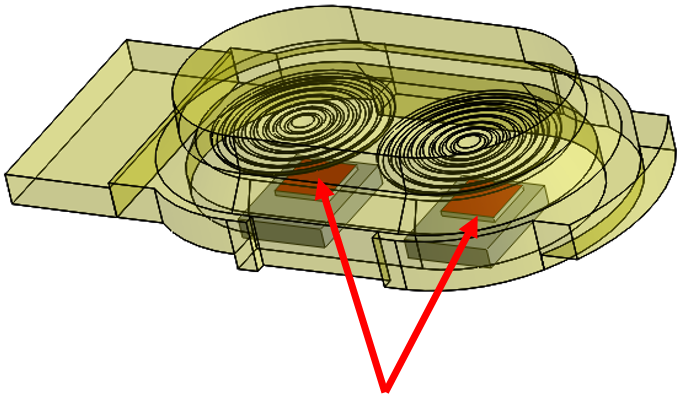

Dual color temperature flash development – 3D Legned

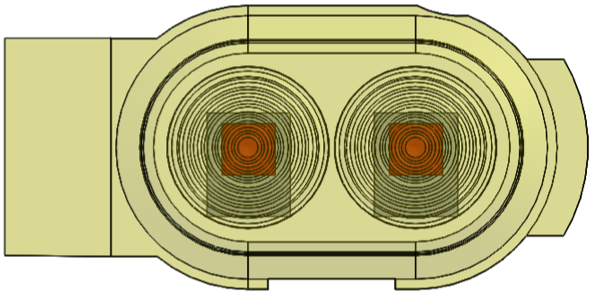

Flash Lens

Led

LED Dual color temperature flash development

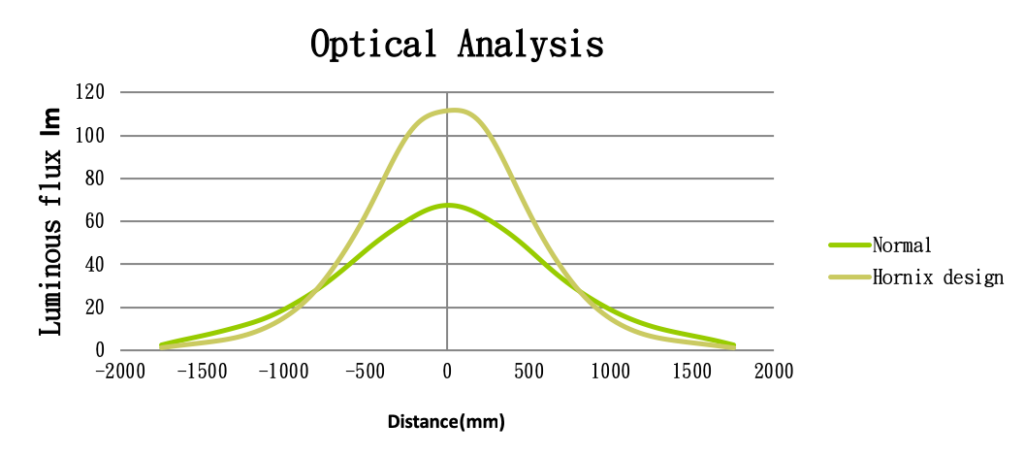

illuminance Distribution

Normal(no lens)

Hornix Design

Normal(no lens)

Hornix Design

Professional Optical Simulation Analysis

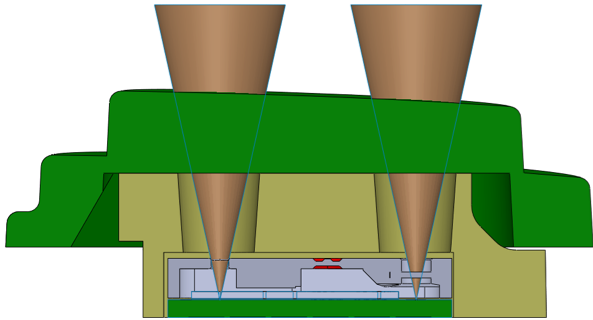

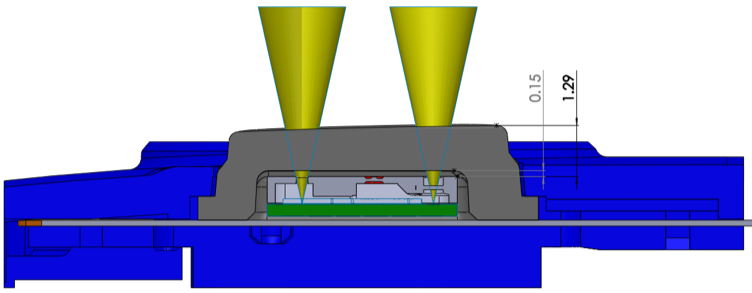

Light laser has high collimation and the lens light threshold is upgrade. The development of lens technology has greatly improved product development efficiency and product practical functionality.

Over-molding Develop

Laser-Aided Focusing

For special product requirements, we have developed an optical two-shot solution.

Combining two different physical properties of plastic on a single product

Fully compliant with high efficiency and high capacity requirements

Plastic materials can be used from general grade to optical grade(PMMA/PC/Silicone)

- Silicone have High heat and no aging, maintain optical properties, can be applied to double shots

Laser Crosstalk Analysis

Insert Molding & Design Development

Glass Insert molding (thickness 0.11mm only)

LED Wire bracket Insert molding

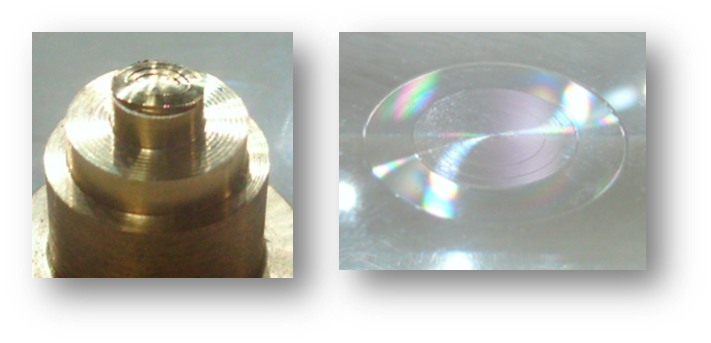

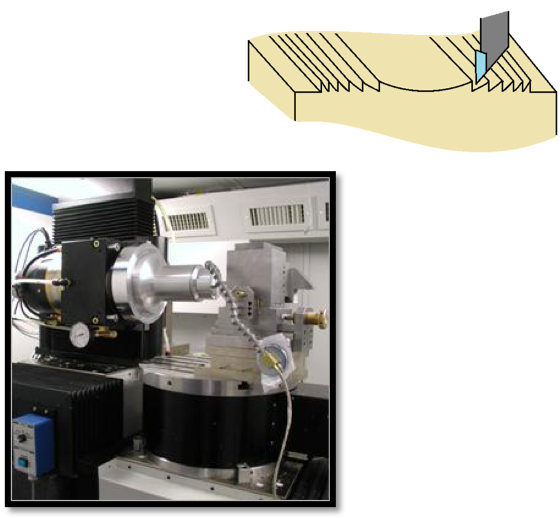

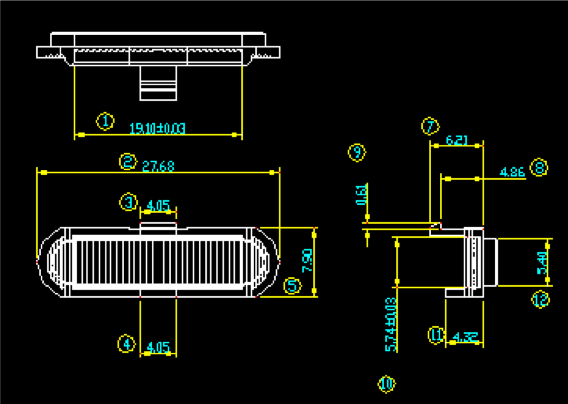

Nonlinear Ultra-precision Machining Technology

For kinds of Fresnel, convex and concave surfaces, nanostructures and ultra-hard materials processing can meet the requirements of optical mirrors.

Tiny dimensional accuracy X/Y/Z : 0.1 μm

Large workpiece machining X/Y/Z : 30 cm / 30 cm / 10 cm

Minimum angular accuracy of 0.01 degrees

Repeat positioning accuracy X/Y/Z : ±0.5 μm

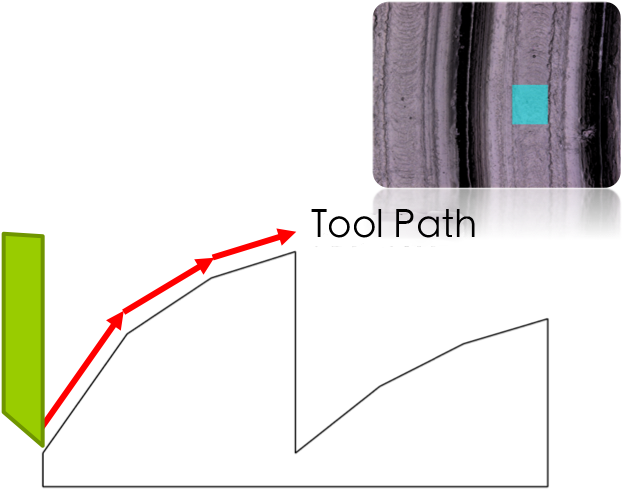

General Mold Processing / Ultra-precision Machining

General machining using point data for tool path control:

- R Angle>R0.02mm

- The surface needs to be polished after processing, and the polished back type cannot be predicted.

- Face type compensation needs to re-enter point information

- The equipment is cheap and the threshold is low.

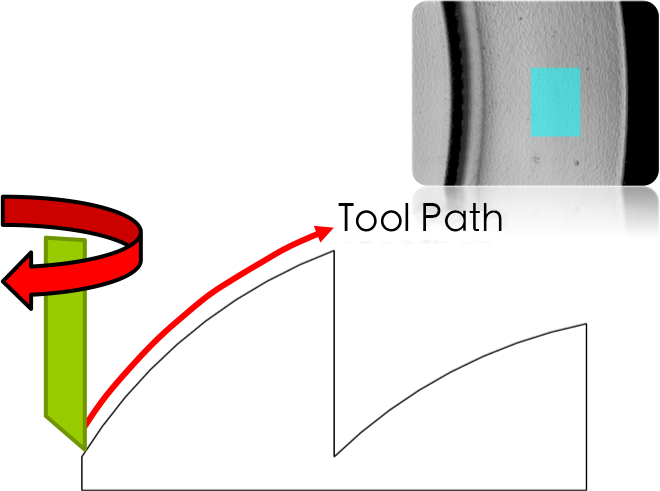

Ultra-precision machining uses equations for tool path control:

- R Angle<R0.015mm

- Better surface roughness Ra<0.02 um

- Surface accuracy is easy to control < 0.1um

- Face type can be compensated directly

Nonlinear Ultra-precision Machining Technology

Assist customers create 2D&3D surfaces and complex machining surfaces, supplemented by flow path analysis and CAM simulation analysis to significantly improve the feasibility and integrity of the process.

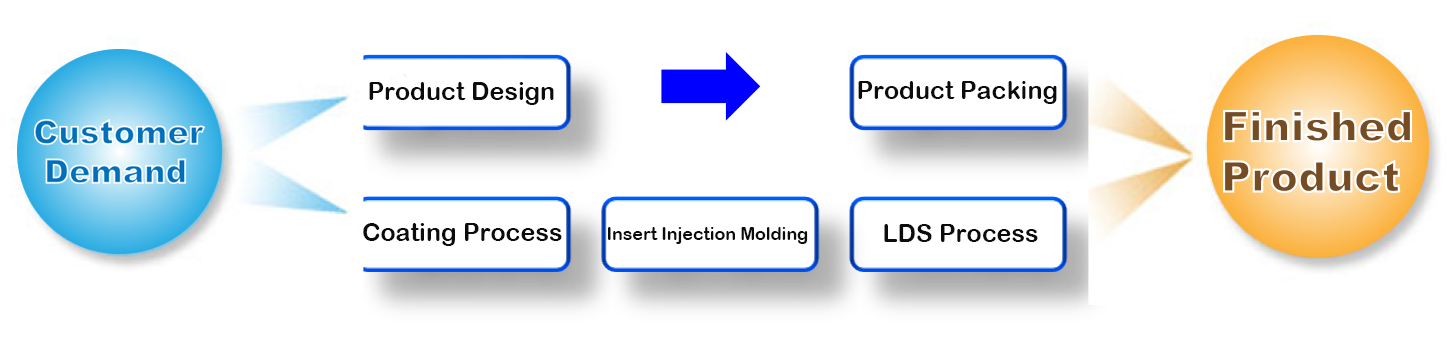

Process Integration

Committed to customer service, process integration provides customers with more speed and higher efficiency solutions, which can provide customers with more and better choices in both the embedded process and the coating process. Total Solutions enables customers to demonstrate the best performance in product development.

Provide customer service and

professional integrity of manufacturing quality

Core Value

As a supplier of electronic components for major international brands, we have always been “developing technology, quality first, rapid mass production” as the core value. Ours goal is to create the best tacit understanding in the electronic components industry together with internationally renowned manufacturers, becoming the best supplier. Our professionalism and constant innovation will be your best choice.